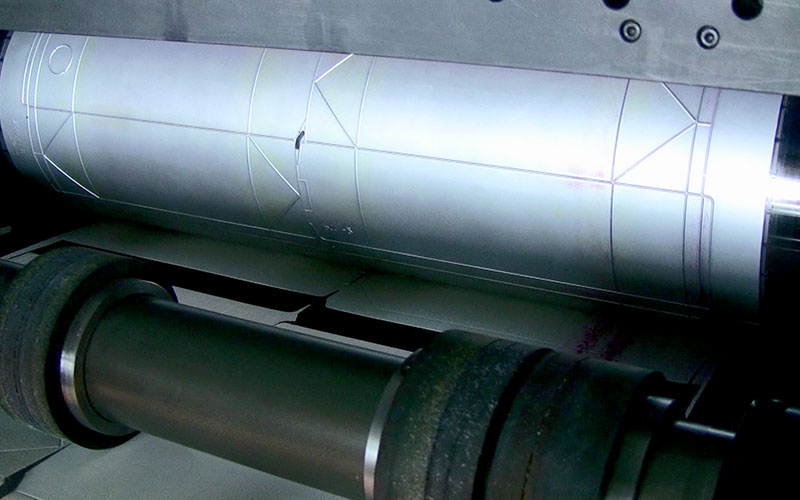

Rotary Die Cutting - LP series

In 2007, the LP series die cutting system was launched to handle the rigorous nature of liquid packaging converting. This massive structure was designed with 80 mm tapered journals and very substantial frame structures. All elements of the CP series system were incorporated in this system as well as many new tool-less features making this our most advance carton converting system today.

The LP series die cutter is extremely rugged and fast to change over. This modular based system was designed specifically for liquid packaging but works excellent for all folding carton applications. This system is designed to run any board caliper from 10 pt up to 30 pt (250 μm to 760 μm).

Specifications:

- Width: 27" - 32" (700 - 825mm)

- Repeat Range: 22" - 40" (560 - 1020mm)

- Maximum speed: 800 f/m (240 m/m)

Options

Features

Die Modules

- Heavy duty frames built with 6 inch thick base casting and 2 inch side frames provides superb rotational accuracy and a vibration free operation at full production speeds

- Large 80 mm tapered journals allows for deflection free operation at full cutting load

- High capacity gap adjust mechanism provides gap adjustments of 0.0001 inches in seconds

- Using our exclusive Automatic Die Loader, flexible steel dies are precisely registered and mounted together all in one motion - off-line die make-ready can be accomplished in less than 2 minutes resulting in accurate mounting each time the dies are used

Rotary Pin Stripping

- The LP series modules use integrated outboard rotary pin strippers to effortlessly remove island, middle, and side scrap from any carton configuration

- Universal stripping disc design allows multiple jobs to be run on the same discs so tooling costs are minimized

- A rigid robust frame design allows for zero waste between cartons and as low as 3mm of side trim

- All components are quick release so discs, combs, and support rails are very easy to change

Delivery System

- The LP series delivery system is designed to handle cartons from 4 inches long right up to 30 inches long

- A dual stage skew conveyor, driven by two servo motors, allows cartons to be precisely collected and de-nested at line speed and then aggressively accelerated through the second stage for a smooth landing on the shingling conveyor

- Skew lanes are mounted on liner bearings and have a pneumatically controlled lift which makes for easy set-up and adjustments during a make-ready

- The long shingling conveyor is designed for maximum stack height so carton jogging and handling is minimized

- Batcher stacker is also available if customers prefer minimal operator handling